A Practical Guide to Implementing 5S Methodology at Workplace

Do you frequently search for files among a heap of things at your workplace? Do you feel that you are wasting a great deal of time in completing unnecessary processes? So, it probably means your office isn’t organized properly. A safe, clean and efficient workplace is the prerequisite for optimal performance. Continuous improvement is not a hard nut to crack. It is a goal that all organizations must strive to attain. Here's a Practical Guide to 5S Methodology.

What is 5S methodology?

5S is a popular methodology in Lean Six Sigma that aims at eliminating waste and creating an organized and clean working environment. As per the Lean principle, anything that doesn’t add value can be termed as waste. 5S is a Lean Six Sigma tool that we can implement in every organization regardless of the industry.

It will give you greater results when everyone in the organization realizes its value and works together towards achieving it. The main advantage of 5S is that it allows you to improve efficiency and also productivity with small and simple changes.

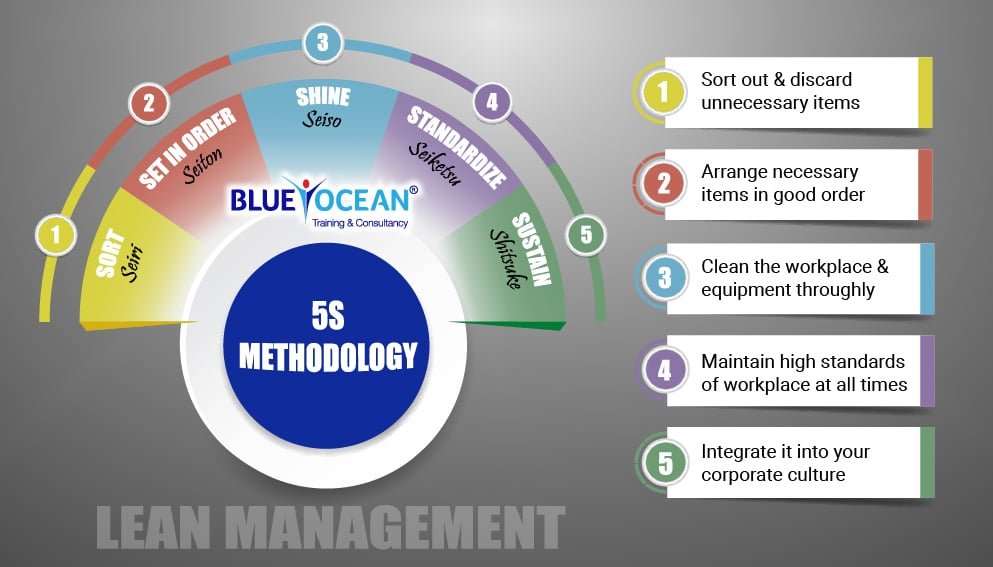

So, what does the 5S stand for? These are the five steps that start with the letter S. They are:

- Sort: Differentiate between the needed and unneeded items

- Set in order: Organize the essential items in a systematic order that allows easy retrieval

- Shine: Clean the office environment

- Standardize: Make all the above-mentioned steps a standard practice

- Sustain: Incorporate 5S into the workplace culture for better results

Importance of 5S methodology in the workplace

5S methodology is one of the most effective tools to eliminate waste from your organization. It doesn’t need huge investment and technical excellence during implementation. This certainly makes it easy for even small companies to adopt 5S to improve efficiency.

Benefits of 5S

- Reduce waste at the workplace

- Saves time required to find misplaced tools

- A well-maintained workplace ensures safety

- Improves the visual aspect of the office

- Drives continuous improvement

- Enhances the workflow

5S implementation

Implementing 5S is a piece of cake if you have a vibrant team that works towards attaining a single goal. If you spend some time with your team and prepare an action plan, it will certainly be a simple yet effective tool to organize the workplace in a perfect way.

Developing an action plan

Before implementing 5S at the workplace, the management has to ensure that the employees are aware of the benefits and needs of the new methodology. The time and financial investment will be futile if they are not willing to cooperate. It is essential to communicate its benefits to even the bottom line to ensure there are no challenges in implementation. Once the employees are on the same page, make an action plan to implement it.

Sort

Sort or red tag activity aims at differentiating between the necessary and unnecessary items at the workplace. Add red tags to the items that you need to remove. Also, we must provide red tags for unsafe or with no definite purpose type of items. Dispose all tagged items to the pre-decided area accordingly.

Set in order

Once the red-tagged items are removed, keep all the necessary items in an order. While doing this, place the items based on the frequency of their use. For instance, items that are used daily must be placed at the point of use.

Shine

Clean up the workplace to remove waste, dirt and hazards. At this stage, also look for things that have defects and safety issues. Those items have to be either replaced or repaired.

Standardize

Though you have finished the main three steps that require time and effort, this is the most important step. We must give instructions to all employees on how to follow these steps every day and make it a standard practice.

Sustain

Improvement is not a one-time process, it is continuous. Lean methodologies rely on the concept of continuous improvement. 5S has to be integrated into the company’s culture. Regular monitoring of the 5S activities, appreciating the efforts and providing reminders using newsletters are part of the sustaining procedures.

If you decide to implement 5S in the workplace, make sure that all employees are willing to cooperate on this on a long-term basis. There must also be a system to train new hires on the same. If implemented and followed in the right way, 5S can certainly improve productivity to a great extent.

The staff will never have to waste their time in search of some important documents among a pile of things. Once 5S is successfully implemented at the workplace, you can definitely ensure that the sixth S is safe.

Learn more about 5S methodology

Do you wish to learn more about 5S methodology? Attend a course in 5S methodology and learn how to implement it in your organization with the help of experts in the field.